Location: Washington, D.C.

Project Scope: Installation of over 100 3-6” caliper trees, over 400,000 blue crocus bulbs, 4,000 shrubs, 550 perennials, grasses and groundcover, 12,000 SF of mulch, 73,000 SF of drain fabrics, 10,000 SF of pavers, 95,000 SF of concrete sidewalks and subslabs, 1,400 LF of security barrier walls, 2,200 LF of split-faced granite curbing, 10,000 tons of gravel, 10,000 CY of manufactured soil mixes, 16,000 LF of drip irrigation and 4,000 SF of spray irrigation.

Installed By: Virginia Landscape Construction Branch

Industry Awards Won: National Association of Landscape Professionals (NALP) 2017 Grand Award, Landscape Contractors Association (LCA) 2017 Grand Award

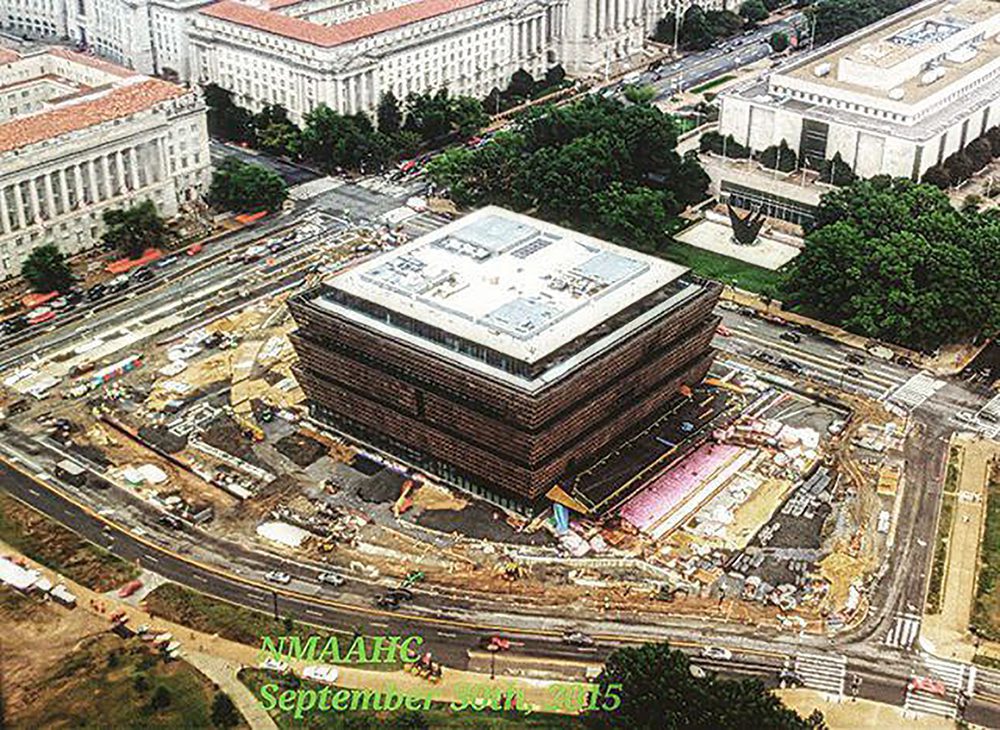

Site Description: Occupying the last available space on the National Mall, the Smithsonian’s National Museum of African American History and Culture (NMAAHC) was completed in the spring of 2016. The landscape design is intended to integrate the space into the Washington Monument grounds through the use of long sweeping curves, careful groupings of trees, and soft rolling topography. A plant palette was developed that references broad overall themes found in the museum. The understory trees are all white-flowering, which is a color that signifies spirituality; and early-flowering blue crocus bulbs were selected to be both welcoming and signify hope and optimism at the end of winter. Trees play a major role on the site. All street trees surrounding the site are elms—different cultivars and spacing to match existing trees on the streets that border the site (14th, 15th, and Constitution Ave.) Within the site, tree species are clustered in informal groups of shade trees and understory trees. The character of the tree species changes from trees with robust, strong presence on the north side (to evoke the strength and resiliency of the African American culture) to trees with a lighter presence on the south side (to allow for more of an emphasis on reflection near the fountain. The landscape plays an integral part in the overall design and links the five-acre site into the larger composition of the national mall, serving as a critical component of the museum experience.

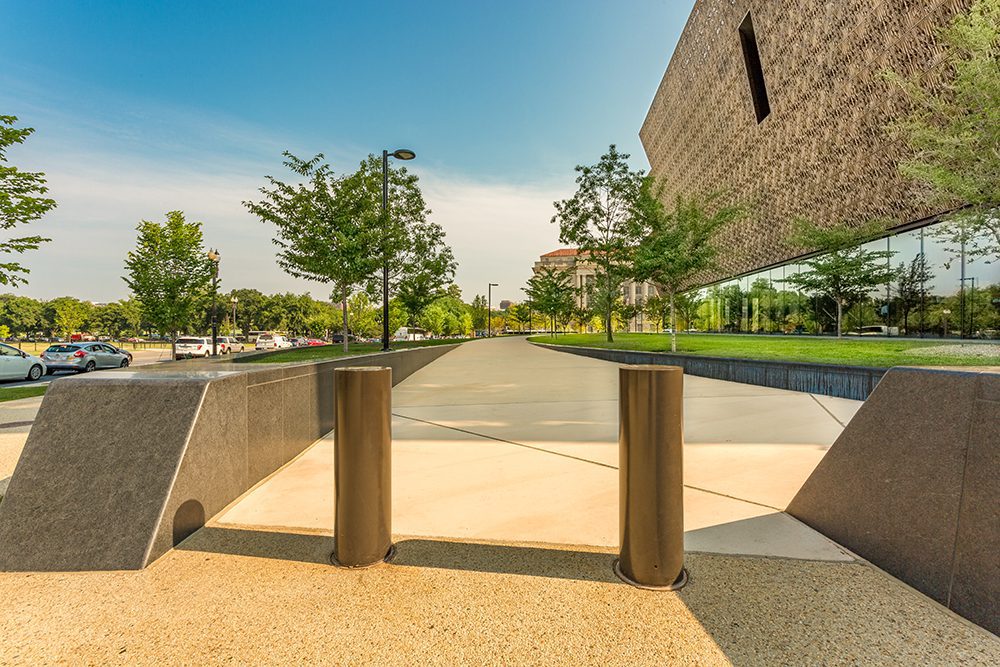

Challenges & Solutions: Due to the site’s DC location, there was a need for high security. Granite-clad concrete security walls and bollards were installed early on in the project. Crews built 3’ ramps to move materials over the barriers—all of which were constructed and deconstructed daily. Heavy equipment wasn’t permitted close to the building due to the job’s over-structure nature, necessitating deliveries be made to the project’s perimeter then moved again using Georgia buggies and wheelbarrows.

Weather issues—both rain and snow—caused 2/3 of the project’s scope to be condensed into a four month schedule. There were 220 different contractors on site— along with many decision-makers including a trio of general contractors, four architects, more than 30 consultants and dozens of stakeholders representing The Smithsonian, Washington DC and multiple federal agencies—all of which were working simultaneously to complete the high-profile project on time for the September 2016 opening.

Photos & Descriptions:

With very limited staging areas on site and the volume of work and various trades, materials that couldn’t be scheduled as Just-In-Time deliveries and immediately installed were often moved several times as staging areas became active work areas.

Photo Credit: Michael Barnes, Smithsonian

These 400,000 crocus bulbs were planted nearly a year ahead of the project’s opening date to help signify hope and optimism at the end of winter. Sourcing that number of bulbs—which came from The Netherlands—was a challenge for purchasers and it took approximately 10 crewmembers nearly five weeks to properly space and install them.

A two-man crew used a specially created lattice tool as a guide to evenly spray paint holes for approval by the landscape architect. Then a six-man crew used 1 ½” spade bits to bore down through the sod into the soil with a third crew following behind on hands and knees to place three bulbs per hole all 9” on center. Adjustments had to be made along the way in areas where soil had settled below the turf requiring corrections to grade before the bulb installation could even be completed.

Hundreds of man hours were expended using laser levels to ensure precise grading and installation of hardscape, walls and walkways. Planning and re-planning were crucial to avoid lost time on this project and to ensure its successful outcome.

There was a lot of planning that went into the installation of the irrigation system. All the hardscape, surfaces, walls, footings and subslabs, sleeves and penetrations had to be completed with pinpoint accuracy to ensure pass through of the irrigation lines to ultimately reach all the planting beds. The Maxicom system, which ties to the NOAA system used for the National Mall, consists of 905 spray heads and 35 zones—all of which can be controlled remotely.

We were responsible for the fountain base, which required close coordination with the fountain contractor. Numerous shop drawings, submittals and requests for information were all managed, coordinated and expedited to address the exact tolerances necessary to ensure that the dimensional stone fountain and drains worked symbiotically to produce a one of a kind product. Over 220 yards of concrete was delivered to this area via a concrete pump truck to create the base, troughs and walls.

There was a real unity and esprit de corps between all parties involved. The general contractor, design team, landscape contractor, architect, Smithsonian Foundation and numerous DC agencies—from Recreation & Parks to The Water Department—worked collegially to solve problems and move the project forward to meet the open date.

The nearly 100 trees on this site are clustered in in informal groups of shade and understory trees. The building’s west side, pictured here, embodies strong tree character with a mix of shade trees (Live Oak and Scarlet Oak) and Cherry trees to begin the transition to the lighter character of the building’s south side. This side also ties to the understory tree palate of the Washington Monument grounds which are adjacent.

Curved radius walls had to have precise 2” tolerances in order for there to be a small air gap that allowed for the expansion and contraction once the granite veneer was installed over top. Tremendous coordination between our site personnel and the granite vendor with shop drawings, inspections and triple checking of everything before, during and after the pours was essential to ensure this finished product.

Over 95,000 SF of concrete walkways and subslabs were installed and included colored concrete and exposed pea gravel aggregate. A concrete pump truck was used to deliver material in hard to access areas.

There was 2200 LF of split-faced granite curb installed on this site. Standard curbs in D.C. are specified as Mount Airy granite, which is harvested from a quarry in North Carolina and shipped several hundred miles to the site.

Ten thousand SF of pavers crisscross the site, often juxtaposed against colored concrete, turf and exposed aggregate to provide visual interest.

Five hundred truckloads of gravel; 625 truckloads of soil and 15 tractor trailer loads of plant material (including trees) and 92 loads of concrete were delivered; and 52 loads of debris/soil were hauled off of the site in a 10 month time period.

Great partnerships, strong communication and necessary resources to work through the details—often out of sequence and out of flow—helped mitigate and eliminate delays that could have taken place ultimately bringing this much-awaited museum to fruition for future generations to enjoy.