By Josh Nichols, Regional Snow Manager

When it comes to winter weather, having a solid game plan in place is critical. Our crews not only perform snow removal but take proactive steps to prevent and minimize the effects of snow and ice on our clients’ properties. Understanding the difference between anti-icing and de-icing is an important first step in the process:

When it comes to winter weather, having a solid game plan in place is critical. Our crews not only perform snow removal but take proactive steps to prevent and minimize the effects of snow and ice on our clients’ properties. Understanding the difference between anti-icing and de-icing is an important first step in the process:

Anti-icing is intended to prevent a strong bond between frozen precipitation or frost and a pavement surface by timely application of a chemical freezing point depressant. De-icing is a when a de-icer is applied to the top of an accumulation of snow, ice, or frost that is already bonded or formed to the pavement surface.

The major benefit of anti-icing is that it breaks the initial bond of snow and ice to the pavement. This will ultimately provide a cleaner clearing of the surfaces and will require less materials in the de-icing process. In some instances, the anti-icing treatment is all that’s required. When anti-icing is not performed, snow will bond to surfaces and clearing will require more time and effort. In addition, it will require more de-icing material to get to clear surfaces. Not every storm should be treated with an anti-icing application, but when done, typically delivers the best results and helps manage overall costs, providing a better final product.

There are several factors that we consider when deciding the correct course of action: air temperature, pavement temperature, type of precipitation, type of surface (asphalt or concrete), and wind speed/direction, to name a few. Both methods of ice control can be accomplished using traditional granular materials or a liquid solution (referred to as a “brine”). There is a wide variety of products available, each with different benefits and cost points. One major benefit of liquid application is that it can be applied up to 48 hours in advance of the storm, as opposed to granular material which should typically be applied closer to the start of the event to prevent unnecessary tracking or displacement of the material from vehicles and pedestrian foot traffic. Additionally, liquid brine doesn’t create a messy situation if the forecasted event does not materialize.

Choosing the Right Equipment

When it comes to applying a liquid brine, it’s important to have the right equipment. First, let’s focus on applying brine to parking lots and roadways. Do you need a gas or electric setup? If you have smaller lots, an electric unit will suffice, but if you are dealing with larger/many lots, gas is your best option. The electric options will limit the number of gallons per minute and speed at which you can operate the truck, whereas gas units will give you the ability to apply more gallons per minute at greater speeds. Gas units will also allow you to utilize a boom that can cover up to three lanes, while the electric units are limited to a single lane application.

When it comes to applying a liquid brine, it’s important to have the right equipment. First, let’s focus on applying brine to parking lots and roadways. Do you need a gas or electric setup? If you have smaller lots, an electric unit will suffice, but if you are dealing with larger/many lots, gas is your best option. The electric options will limit the number of gallons per minute and speed at which you can operate the truck, whereas gas units will give you the ability to apply more gallons per minute at greater speeds. Gas units will also allow you to utilize a boom that can cover up to three lanes, while the electric units are limited to a single lane application.

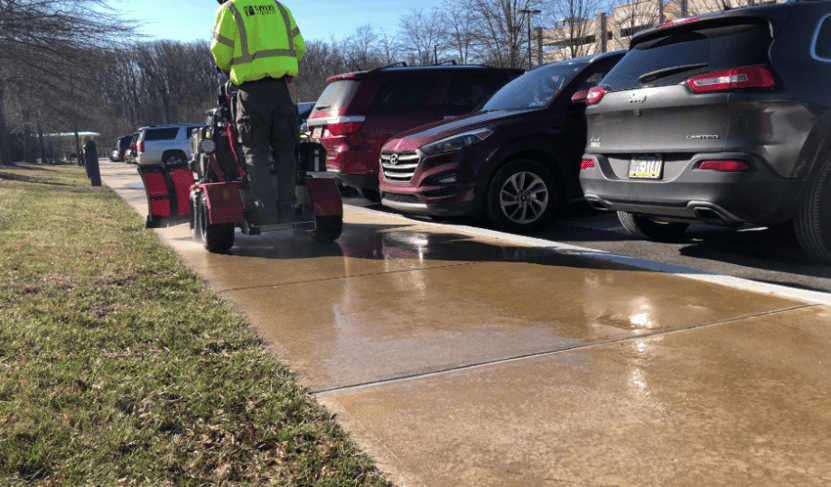

Second, we’ll focus on applying brine to sidewalks. Like the parking lots, gas or electric will provide different options. Both are good, but electric can be an affordable option and provide the output and efficiency you need. I’ve seen folks using the traditional three or four-gallon backpack sprayer. If you are only doing entrances to buildings and are using a specialty product, this is a fine solution. But if you are doing more than that, I’d recommend other options to improve your efficiency, as the backpack sprayer is a slow application process. Depending on the size of your walks, equipment-based options should be considered. The Boss Snow Rator provides the ability to apply liquid in a 3’ pass in a controlled manor. It also has a small hand wand that allows you to treat steps and other areas that the machine can’t access. Alternatively, a UTV with a 50-100 gallon tank will give you greater flexibility for larger sites. This unit comes with a boom that can treat 4’ sections. It also has side sprays called boom busters which will give you the ability to treat either 8’ or 12’ sections, depending on if you have both the right and left boom buster on or just one. This unit also has 100’ of hose to treat steps and other areas the unit can’t access. The other option is to use the hose reel off your gas-powered truck unit. This is good for small sections of walk at building entrances. If you end up using this to treat all the walks on a property, it means you are limiting your ability to treat more parking lots and roadways, which is something that should be considered for you overall brine plan.

How much is enough?

Application rates are critical to getting the desired results. Anti-icing will require less gallons of brine than de-icing requires. It’s important to understand what product you are using and the desired application rates for anti- and de-icing applications. One other thing to consider is parking lots vs. sidewalks. Most parking lots are made of asphalt, while sidewalks are concrete or pavers. The asphalt will tend to be warmer because of the dark color and the vehicular traffic. The sidewalk surfaces will be colder and therefore require a higher application rate to get the desired results.

To provide a visual example, here is a before, during and after picture of a parking lot application. The picture on the left is a brine treatment that was applied to all drive lanes on a commercial lot during the day. The middle picture is when the snow began falling the next day and as it contacts the treated surface, the snow begins melting. The picture on the right shows how all the snow has melted the day after. This was a light dusting, so all treated areas melted. The parking spaces that were not treated still have snow cover. Of course the goal would be to treat all areas at night when there are no cars in the parking lot, but this is not always possible.

Selecting the right approach for each storm is a science and can vary greatly on a storm-by-storm basis. No two storms are the same, nor is the same storm similar in a different location across town. We educate our teams on the latest products, equipment and techniques to make sure our snow tool bag has plenty of options when it comes to attacking a winter weather event. Applying a scientific approach to material applications will allow for the best approach, which ultimately provides a safer environment for tenants and customers.