By Reid Altavilla, Corporate Fleet Manager

Over the last few months, our shop mechanics have made multiple modifications to each of our leaf vacuums in all branches to increase operator safety and efficiency and minimize overall equipment repair costs.

Over the last few months, our shop mechanics have made multiple modifications to each of our leaf vacuums in all branches to increase operator safety and efficiency and minimize overall equipment repair costs.

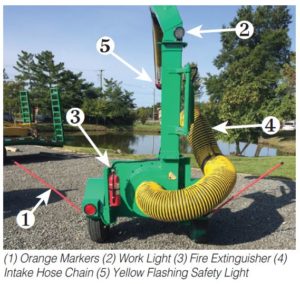

To increase visibility, we have installed orange markers, a yellow flashing safety light, and a white work light on the upper rear portion of the machine.

To increase visibility, we have installed orange markers, a yellow flashing safety light, and a white work light on the upper rear portion of the machine.- We’ve installed a fire extinguisher on the rear of the machine to be prepared in the event of a fire which could be caused by dry leaves and a hot engine.

- We’ve adjusted the length of the intake hose and supporting chain to increase the suction, and limit the potential of clogging by making the hose hang straighter, with the intention of increasing efficiency and operator comfort. Additionally, a more durable intake hose was installed—with a plastic nose cone protector—to eliminate wear to the lower portion of the nose cone. These modifications should help reduce maintenance costs.

We have made these modifications during our “Summer Recon” process along with making sure that the machine is in top operating condition so that we are able to best serve our customers.

To increase visibility, we have installed orange markers, a yellow flashing safety light, and a white work light on the upper rear portion of the machine.

To increase visibility, we have installed orange markers, a yellow flashing safety light, and a white work light on the upper rear portion of the machine.