Image is one of our Ruppert Values, and a key component of that is represented by our fleet. At least twice a year, all vehicles and equipment will go through a multipoint inspection for repair and upkeep during our reconditioning process (a.k.a. recon), which includes cleaning, painting, and providing preventative maintenance on mowers, blowers, trailers, production trucks and more. Our shop personnel will invest anywhere between 600 to 1,800 labor hours per year on the recon process.

Image is one of our Ruppert Values, and a key component of that is represented by our fleet. At least twice a year, all vehicles and equipment will go through a multipoint inspection for repair and upkeep during our reconditioning process (a.k.a. recon), which includes cleaning, painting, and providing preventative maintenance on mowers, blowers, trailers, production trucks and more. Our shop personnel will invest anywhere between 600 to 1,800 labor hours per year on the recon process.

As we prepare for winter recon, we are asking each of our team members who use a company vehicle or equipment on a daily basis to think about the things you can do to help our fleet team uphold and enhance our everyday image, including:

- Timely Maintenance Requests

- Submitting written maintenance requests (not just verbal) so that they can be processed quickly, putting vehicles back on the road and equipment back in the field within 48 hours when possible

- Addressing the small issues proactively before they become bigger issues

- Proper pad maintenance— bringing in vehicles and equipment for scheduled preventative maintenance twice per week for each landscape management crew, including blade sharpening, pressure washing of units, oil/filter changes, lubrication, tire pressure, etc.

- Training on equipment prior to use in the field—proper training will result in less damage to our equipment as well as lower risk of injury to our crew members

- Keeping vehicles and equipment clean and organized—cleaning out vehicle interiors, tracking inventory and ensuring crew assignment sheets are correct

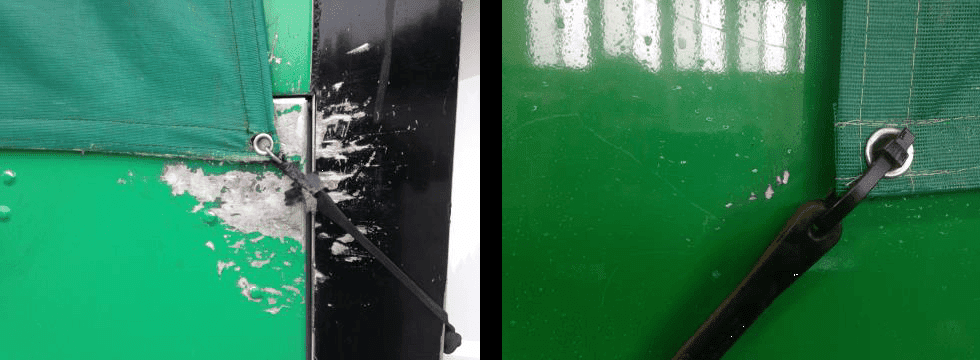

- Making sure metal bungee hooks are NOT touching painted surfaces so that the paint does not get scratched off by the hooks (see photo example)

- Always hook under the truck body when possible

- Always have zip-ties on the tarp end of the bungee

With a little extra effort in the daily use of our equipment and vehicles and the shop team’s comprehensive care during recon time, we will have a sharp looking fleet day in and day out!